TX3R

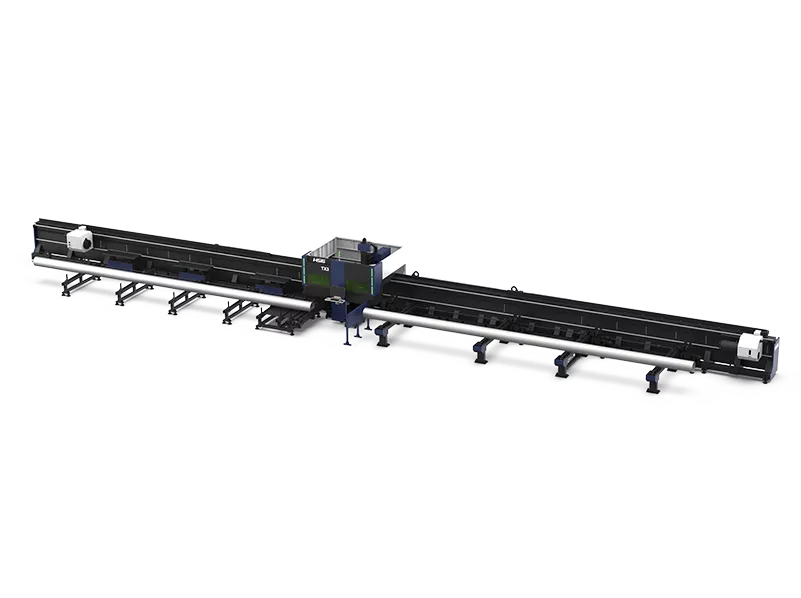

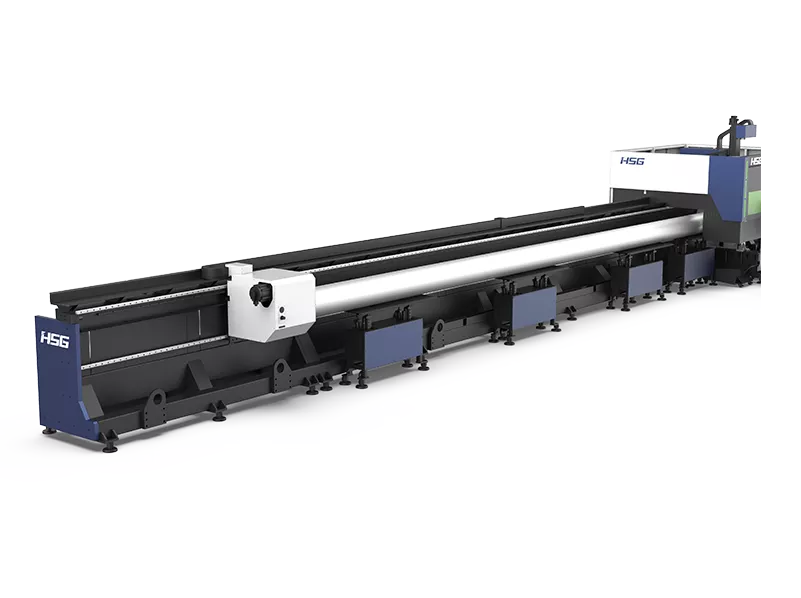

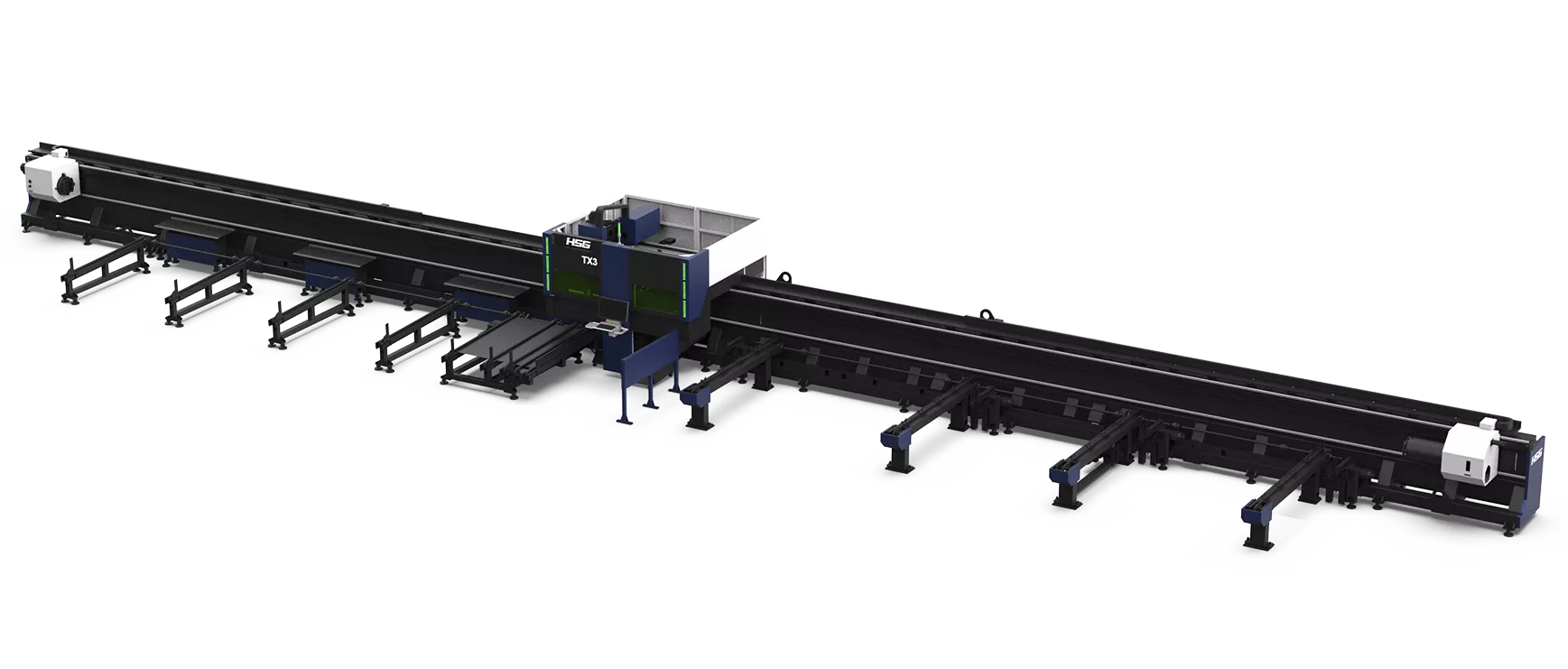

L-shaped heavy-duty lathe bed

Engineered for large and heavy tubes from the ground up,

Heavy-duty side-mounted design, the machine weighs nearly 20 tons,robust and reliable.

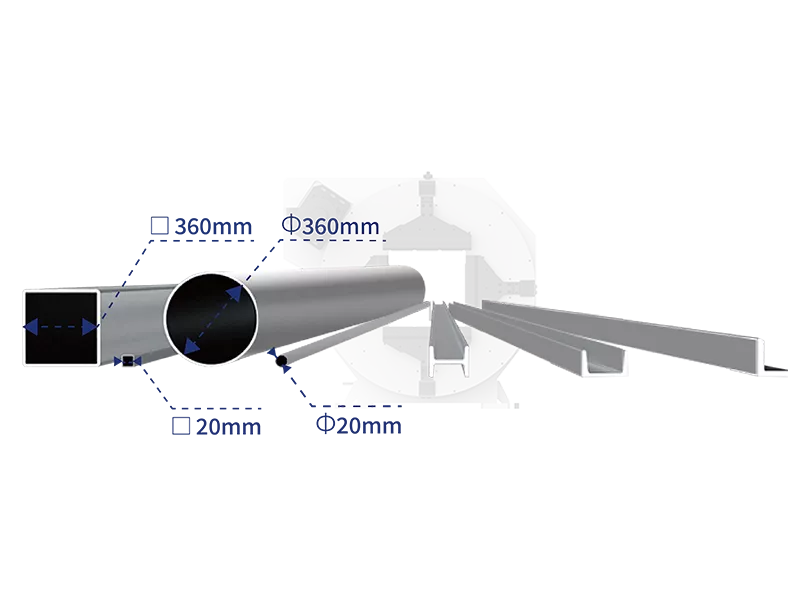

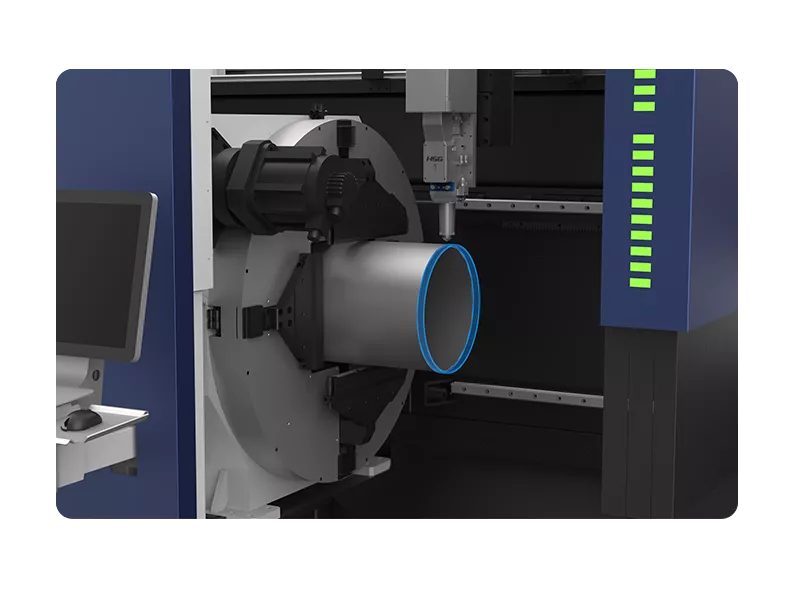

HSG unique intelligent chucks

With the HSG unique intelligent chucks, tubes can be manufactured across the entire clamping range from 40mm to 360mm without the need for retooling.

The chuck has good sealing, avoids cutting smoke and slag pollution, and ensures the stability of the equipment and the long service life.

Automatic loading and unloading

Automatic loading and unloading of heavy pipes, efficient and time-saving, shorten production preparation time.Greatly improves operational safety, saves labor and reduces production costs.

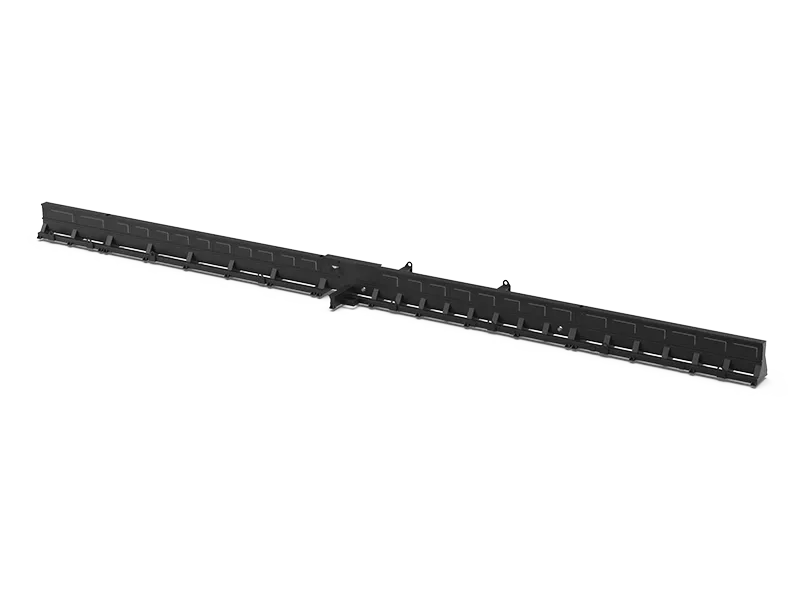

Heavy-duty tube following support system

The heavy-duty tube following support system provides all-round effective support in pipe processing and improves the accuracy of heavy pipe processing.

Zero tailing cutting

Multi-chuck reversing movement realizes zero tailing for heavy pipe cutting and saves material costs.

Quickly process open profiles

The machine is equipped with national-standard profile grippers as standard, which can easily cut angle steel, channel steel and H steel.

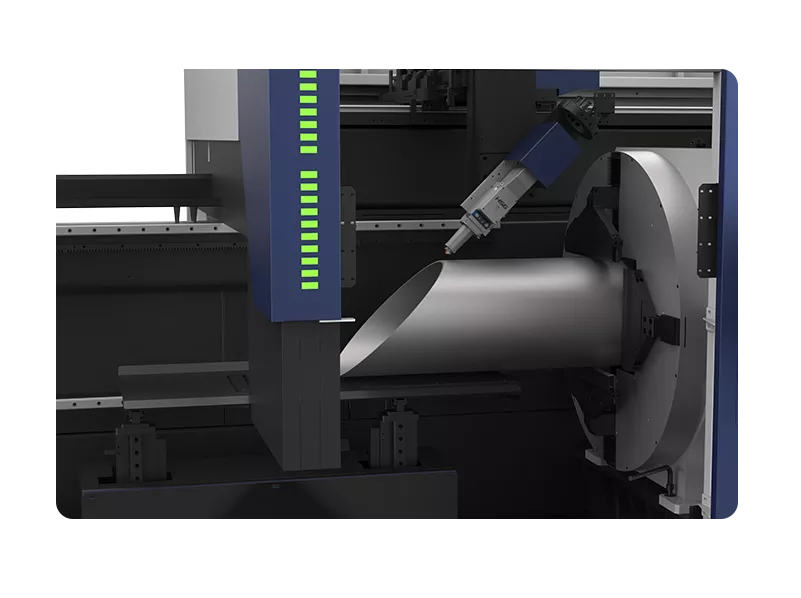

Bevel cuts of up to 45°

Expand your part spectrum and achieve better tube splicing with high-quality bevel cuts up to 45°.

HSG Intelligent Bus Operating System

Thanks to the comprehensive pipe processing application assistance and professional pipe cutting process database with HSG years of accumulated data , tube processing is even more convenient. Clever designs with laser tube cutting simplify your processes.

TX3R

Technical Parameters

- Model

- Power

- X/Y-axis Positioning Accuracy

- Cutting Capacity of Round Tube

- Cutting Capacity of Square Tube

- Weight of Single Tube

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine