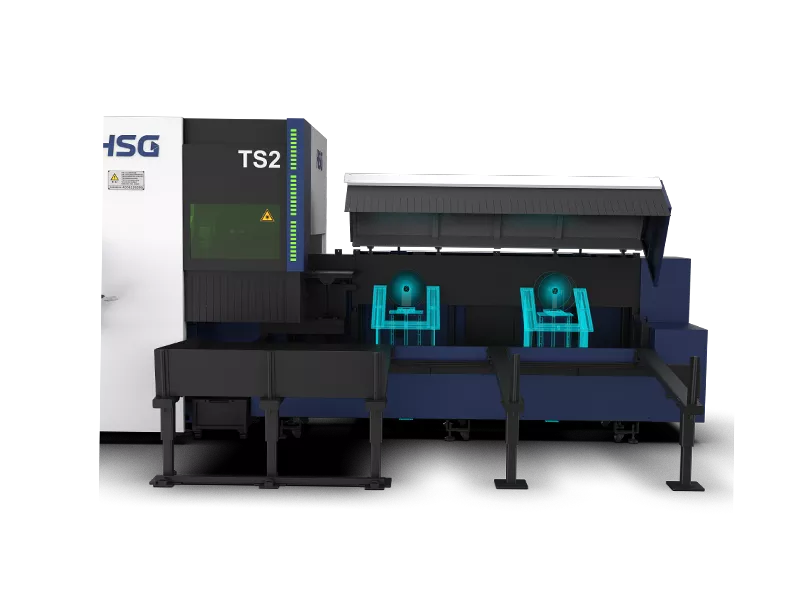

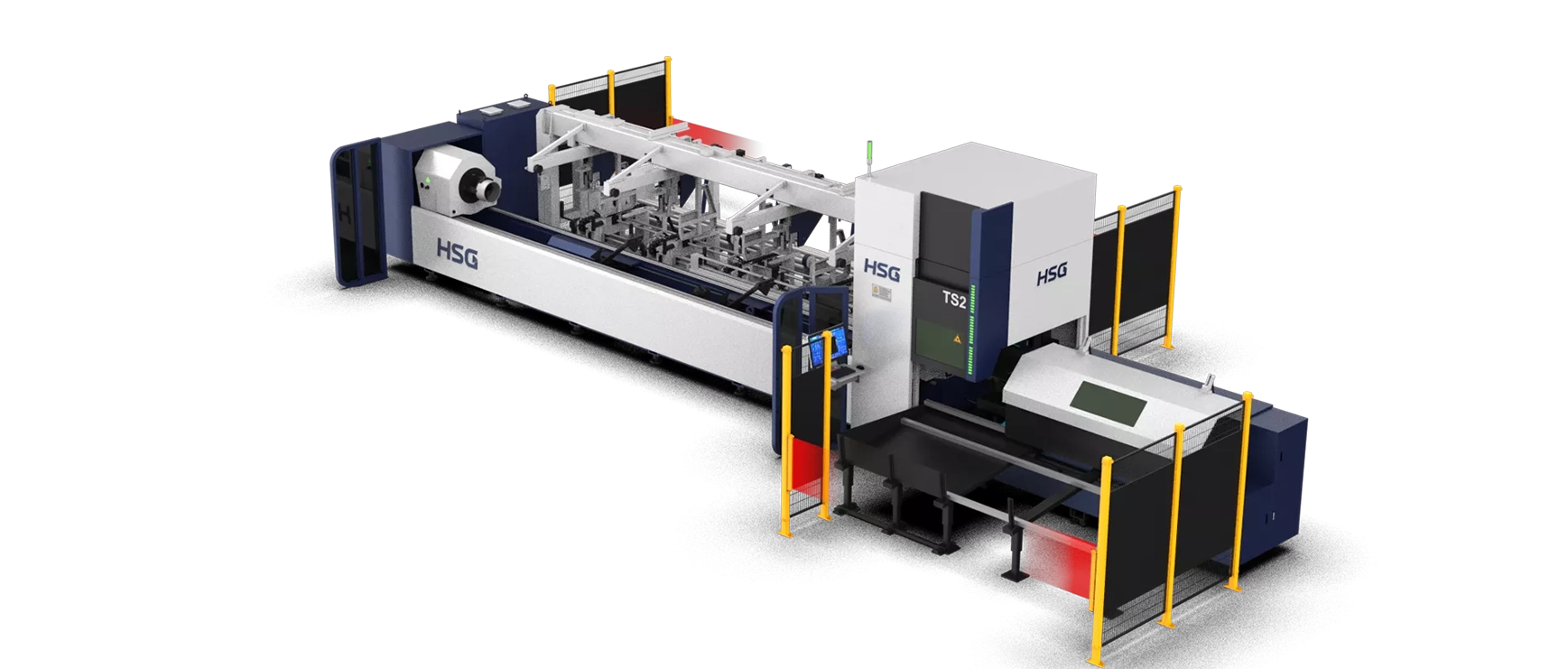

TS2

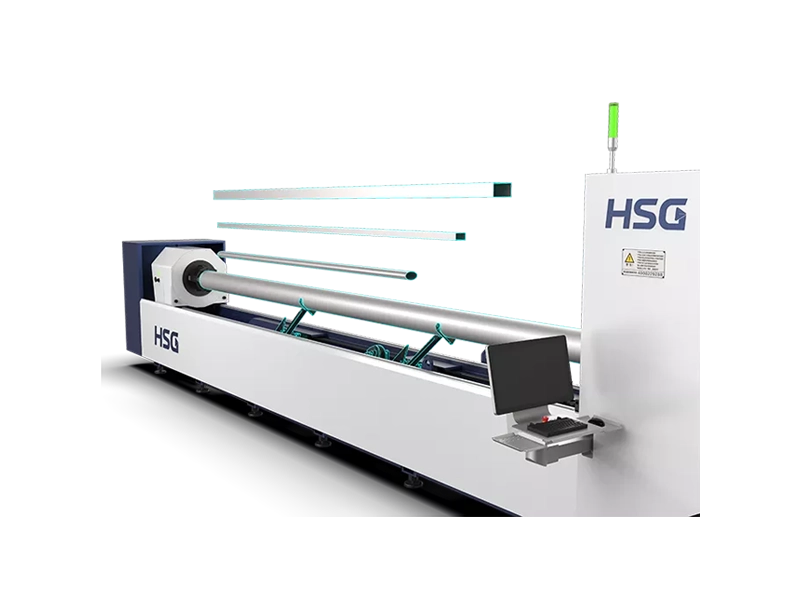

Fast Cutting

The max linkage speed is 140m/min, the acceleration is 1.4G, and the chuck rotation speed is 140r/min. Dramatically shorten the delivery cycle with high-efficiency cutting.

Dynamic Chuck

Two digital intelligent chuck as standard, automatically identify tube size and adjust air pressure and

clamping force within 2 seconds.

At the same time, the rear chuck is equipped with air and dust suction functions, making the

workpiece tube cleaner and maintaining a clean processing environment.

Capability of Multiple Tube Processing

Standard configuration includes two clamps for tubes and profiles, capable of processing tubes with a weight of ≤ 300kg and a diameter range of 12-273mm for round tubes. It also supports cutting profiles such as channel steel, angle steel, and I-beams.

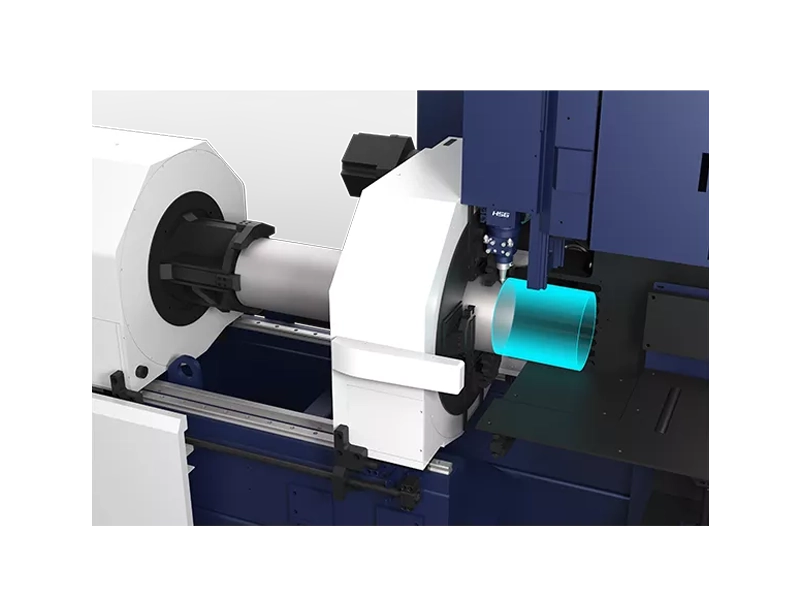

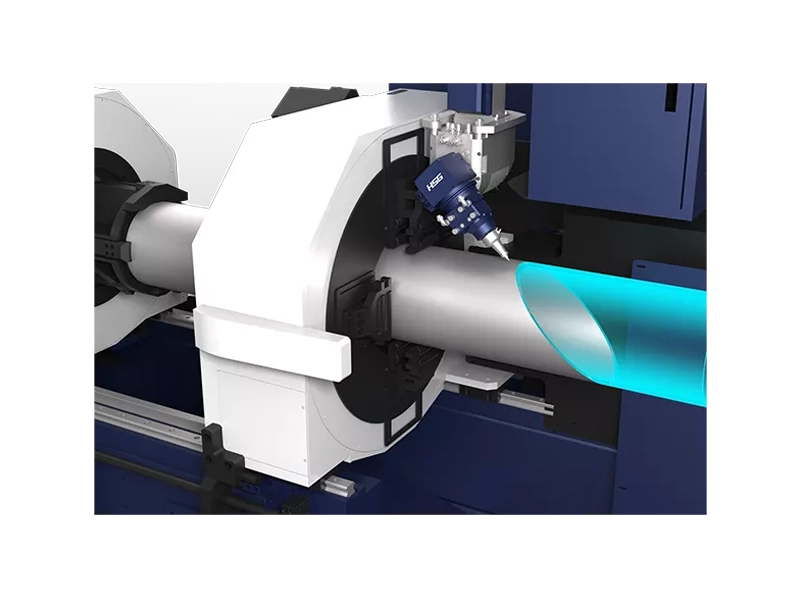

HSG 3D Cutting Technologies (Optional)

HSG-LA4 tube bevel cutting head can be optionally selected to be your secret weapon for complex tube cutting.

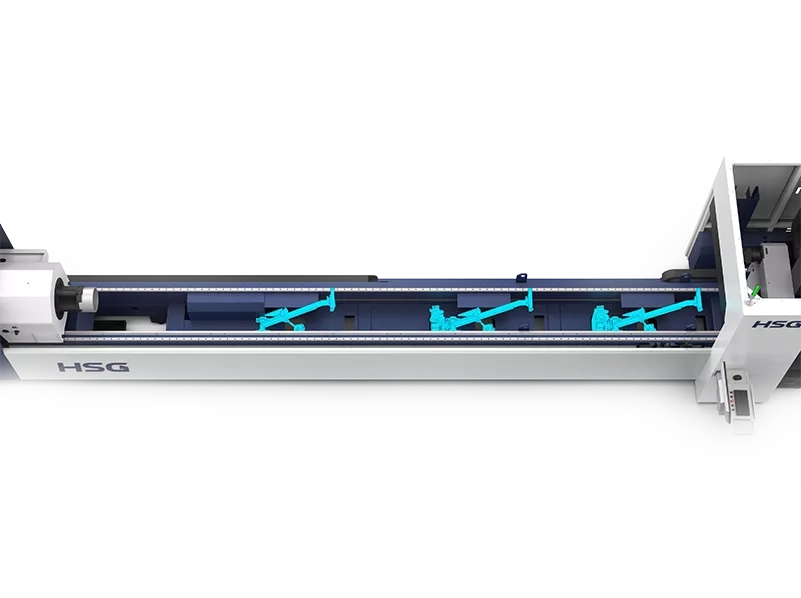

Dynamic Unloading

Intelligent adjustment of position based on the length of the workpiece with one follow-up flip board and two follow-up concave wheels, providing stable support during cutting process.

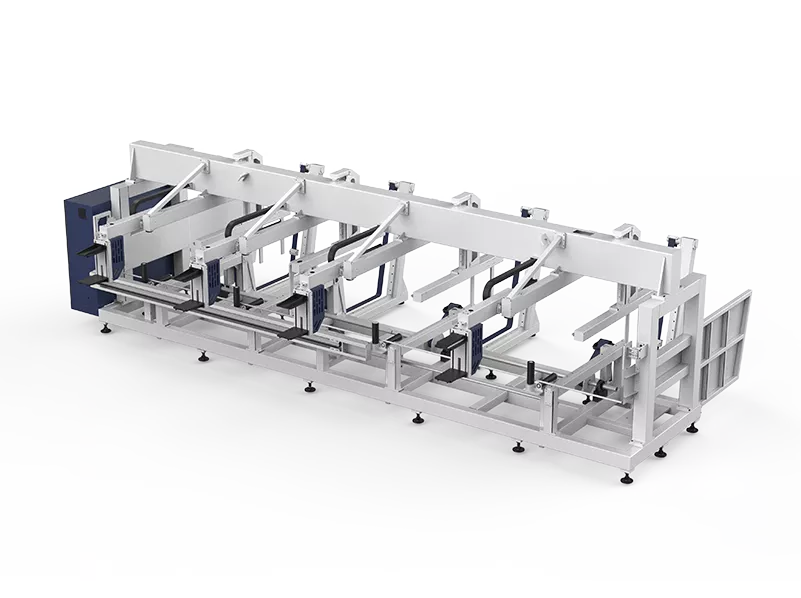

Efficient Automatic Loading Within 25s(Optional)

Optional fully automatic loading. The loading time can be as short as 25 seconds, improving processing efficiency.

Dynamic Support

The machine is equipped with highly sensitive and independent servo follow-up support to ensure stable tube cutting and enhance cutting precision.

HSG-X Intelligent Bus Operating System

Clear interface is convenient for users operating and shows cutting data in real time to save time and

costs.

A number of core functions are shown centrally on the interface to reduce operating steps and users can

easily learn to operate.

Cutting+Drilling+Tapping(Optional)

Integrated laser cutting, hot melt drilling and tapping, for molding at once to reduce processing processes, save labor, greatly shorten processing time and improve production efficiency.

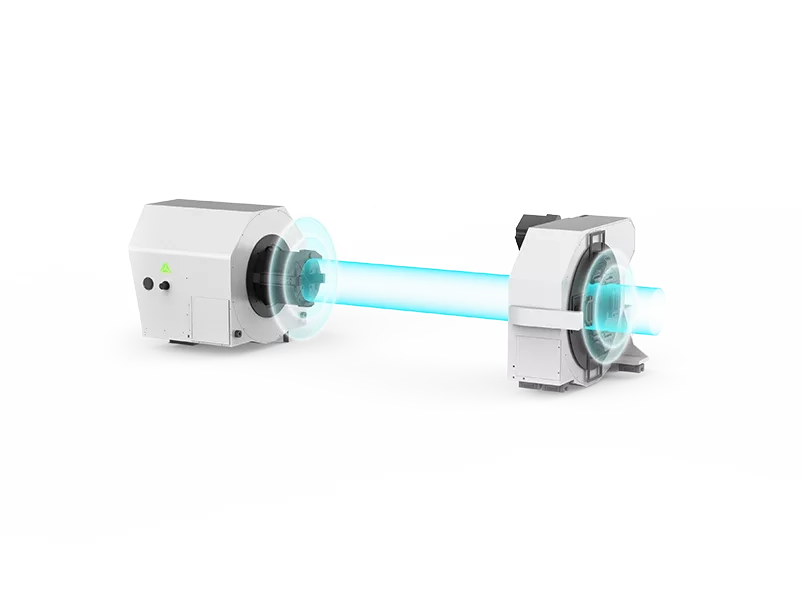

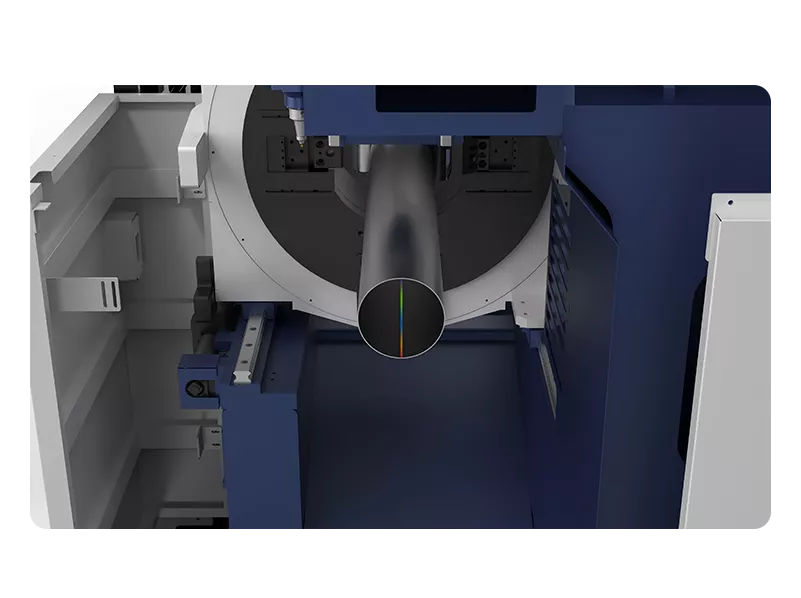

Dynamic Seamline Inner Weld Detection(Optional)

Accurately identifies weld seams from inside the tube, preventing recognition errors caused by external rust or polishing, and reducing scrap rates.

Dynamic Line-Scan Auto Centering(Optional)

Uses blue light to scan the tube, automatically locating the tube center to enhance cutting accuracy.

TS2

Technical Parameters

- Model

- Power

- Cutting Capacity of Round Tube

- Cutting Capacity of Square Tube

- The Range of Tube Length

- Unloading Length

- Acceleration

- Max. Loading Capacity(Single)

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Tube Metal Cutting Machine

Tube Metal Cutting Machine

Sheet and Tube Cutting Machine

Sheet and Tube Cutting Machine

Thermoforming and Processing

Thermoforming and Processing

Bending Machine

Bending Machine

Handheld Laser Welding Machine

Handheld Laser Welding Machine

Automation Equipment

Automation Equipment

Profiles Laser Cutting Machine

Profiles Laser Cutting Machine